The world economic environment is full of uncertainties in the post-pandemic era, and varied problems (sudden changes in market demand, soaring costs, supply disruptions, shortage of funds, rising rents and others) exert greater impact on enterprises, which raise increasing enterprises’ awareness to realize the necessity of intelligent warehousing, and the urgent need for transforming to high density, high efficiency, fast response with less labor cost through continuous optimization and in-depth reform.

To help customers solve the problems brought by warehousing, ZS Robotics, with more than ten years experience in intelligent warehousing, can provide customized, intensive, effective, flexible intelligent warehouse solutions for customers based on different application scenarios.

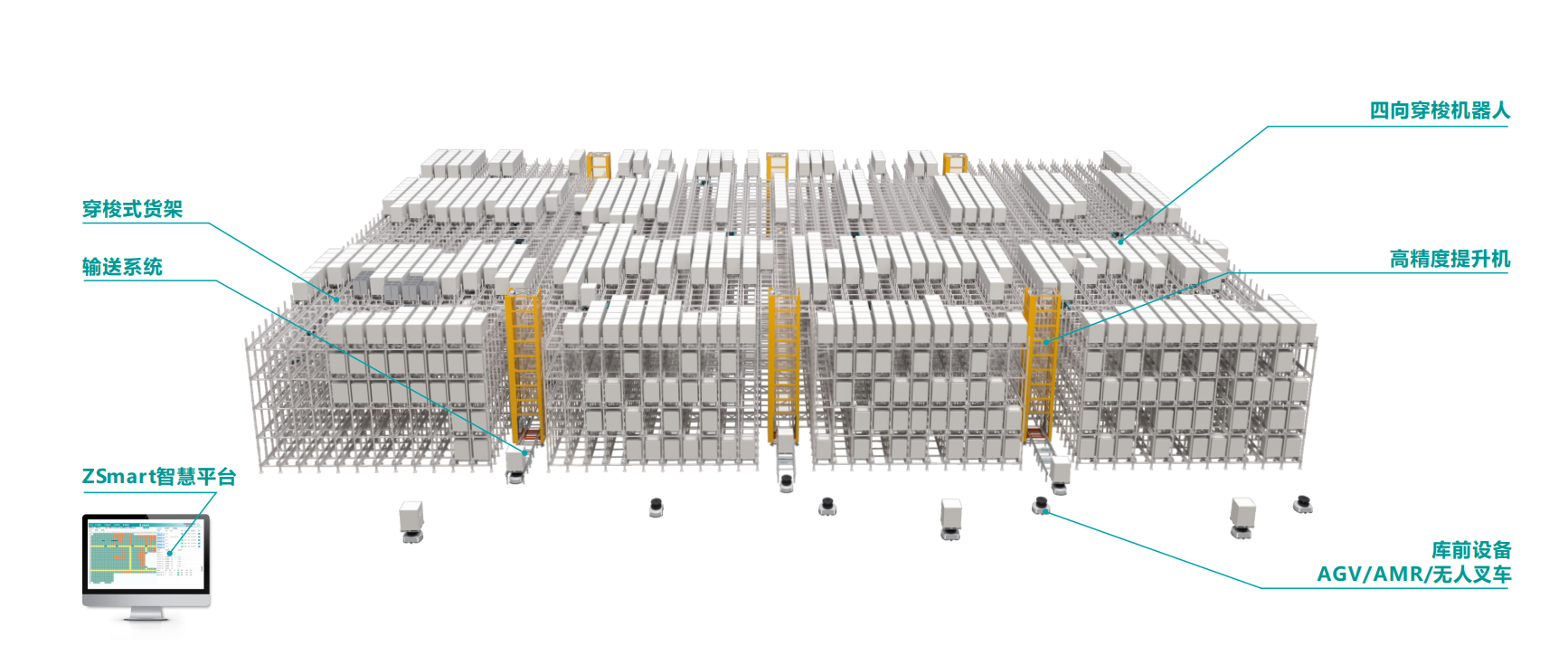

ZS Robotics intelligent warehouse solutions mainly consist of four-way shuttle robots, high-precision hoister, shuttle carrier systems, delivery systems and ZSmart platform (WMS, WCS, RCS, CPS).

Storage-intensive and Improved Efficiency with Reduced Cost

Cost and efficiency are two of the most important indicators for warehouse and factory operations. For traditional warehouse, cargo was piled up on the grounded pallets or shelves where aisles need to be left between shelves. As a result, the utilization rate of warehouse space is very low, especially for the upper space of the warehouse.

In ZS Robotics intelligent warehouse solutions, pallets can be stored at the maximum density. At the same time, a minimum of 165 mm and 210 mm is required at the top and bottom of the high-precision hoister to maximize the utilization rate of the headroom. Compared to traditional manual warehouses and other general three-dimensional warehouses, the overall storage density can be increased by 1.3 - 4 times, and the usable area of the warehouse can be reduced by 50% - 300%. Additionally, ZS Robotics intelligent warehouse solutions support collaborative operation after scheduling vehicles across regions and floors, to meet higher handling capacity at different time period, with overall efficiency increased by at least 20%.

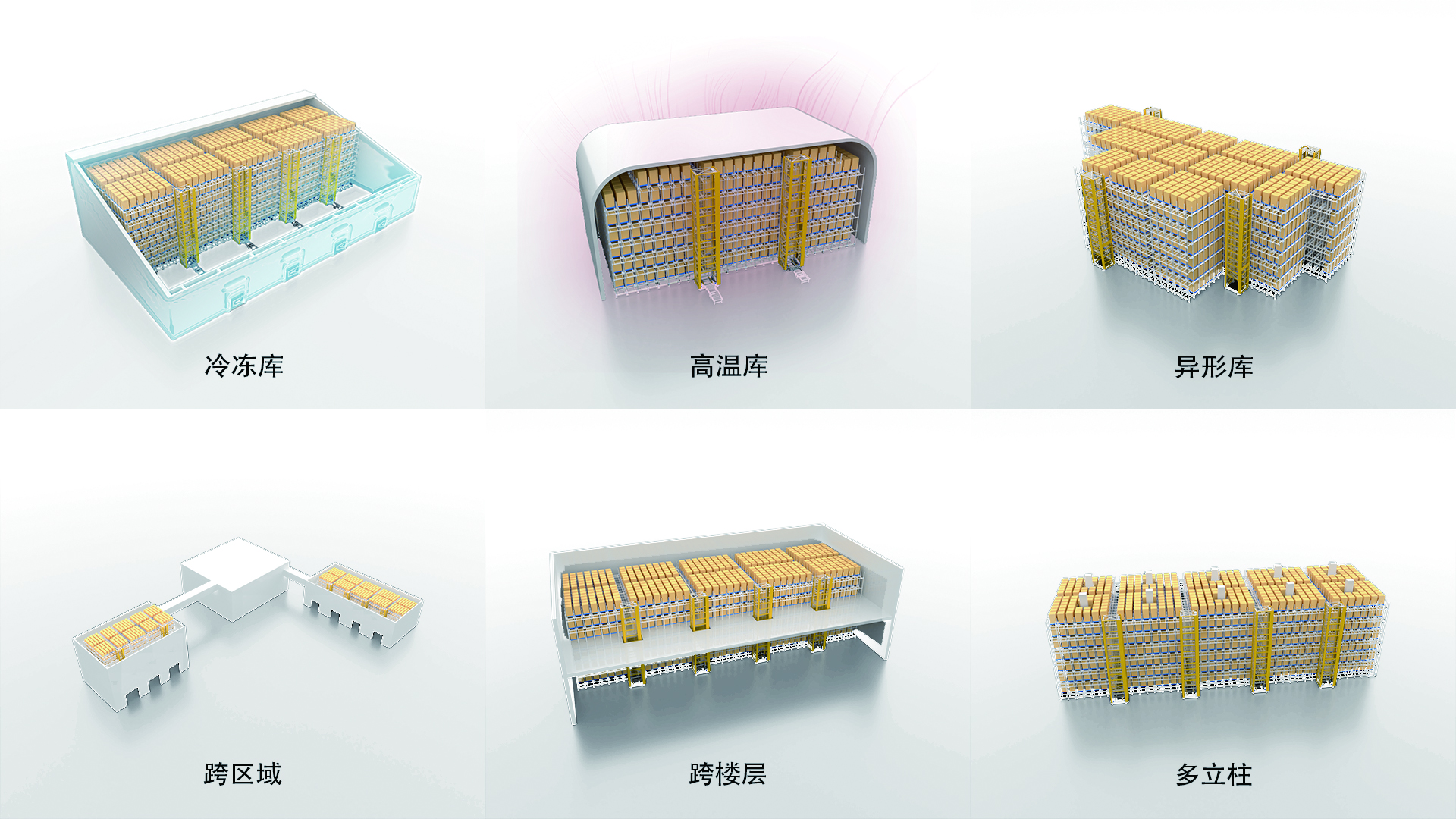

Suitable for Different Scenarios (high temperature, frozen warehouse) with Better Flexibility and Adaptability

The primary advantages for our four-way shuttle robots are better flexibility in storage, excellent adaptability in deployment and suitable for complicated warehousing structures and adverse working conditions, compared to other warehousing equipment. Meanwhile, projects can be expanded flexibly according to customers’ production needs, financial condition and other situations. And staged investment is available for fixed assets.

Five Advantages of ZS Robotics Solutions

Intensive Storage

· Pallets stored at the maximum density

· High utilization rate of head room to optimized space in warehouse

· Efficient and safe scheduling of vehicles in three-dimensional space

· Trajectory of a optimal path available to efficiently avoid obstacles

· Overall system usage not affected by single machine failures

· Easy to transform, deploy and expand

· It can be stored across floors and regions

· It can be implemented in stages, and it only takes 1 hour to deploy additional vehicles

· Set rules for warehouse receiving and delivery as required with intelligent charge strategy

· Flexible allocation of storage depth

· Idle equipments can be scheduled across regions for collaborative operation

· Suitable for irregular warehouses

· Compatible with traditional shuttle shelves

· Suitable for refrigerated, frozen, high temperature and other temperature controlled warehouses

No. 31011502019351

No. 31011502019351